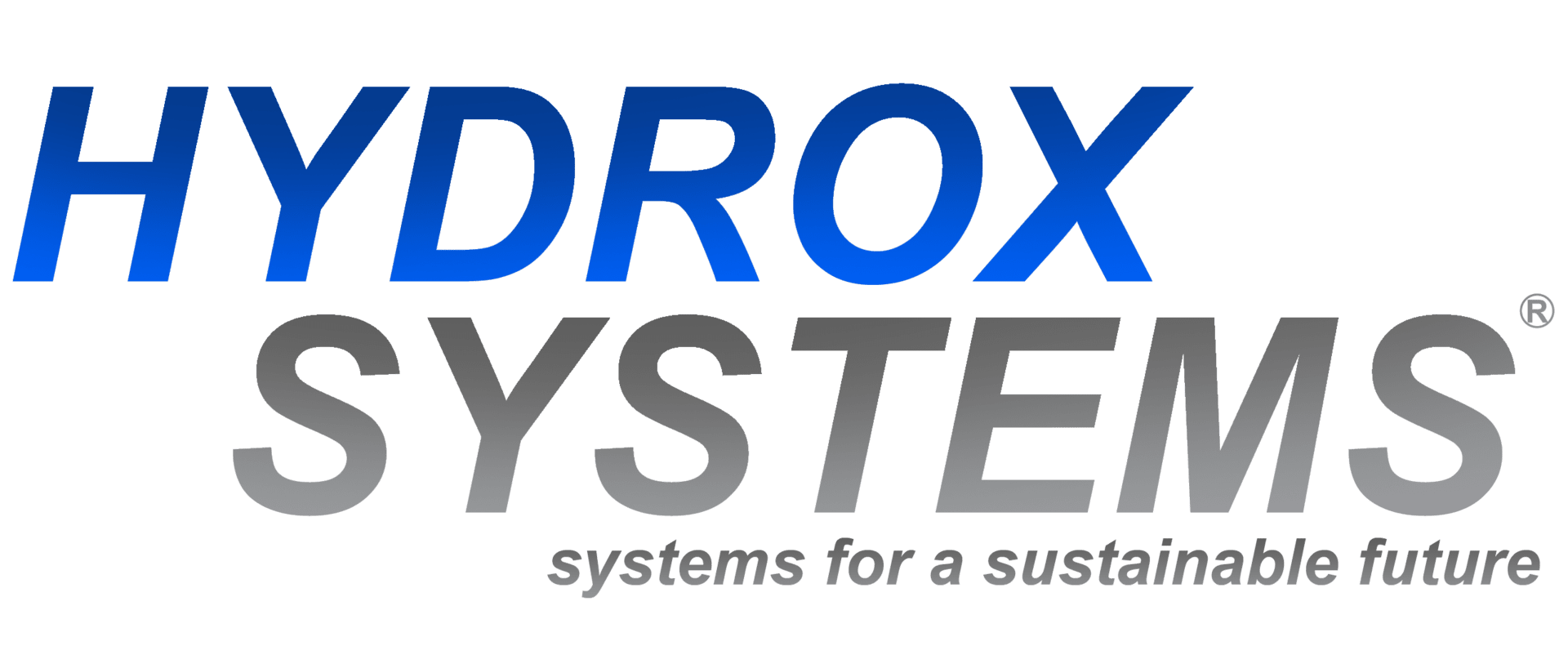

Understanding Electrolysis in Hydrogen Generation

Understanding Electrolysis in Hydrogen Generation

Electrolysis is at the core of modern hydrogen production. It is a clean, efficient, and scalable method of generating hydrogen gas (H2) from water using electricity. As industries, governments, and individuals search for sustainable alternatives to fossil fuels, understanding electrolysis becomes essential. In this article, we’ll explore how electrolysis works, the types of electrolysis, its role in hydrogen technologies like HHO systems, and why it’s vital for the green energy revolution.

🔋 What Is Electrolysis?

Electrolysis is a chemical process that uses electricity to split water (H2O) into its basic elements: hydrogen (H2) and oxygen (O2). The reaction takes place in an electrolyzer, a device with two electrodes submerged in an electrolyte solution.

Basic Formula:

2H2O(l) → 2H2(g) + O2(g)

In simple terms, when you apply a direct current (DC) across the electrodes, hydrogen gas forms at the negative electrode (cathode), and oxygen gas forms at the positive electrode (anode).

🌍 Why Electrolysis Matters in the Green Economy

Electrolysis plays a pivotal role in green hydrogen production, especially when powered by renewable energy sources like solar, wind, or hydro. This makes the entire hydrogen production process carbon-free.

Key Benefits:

- Zero CO2 emissions

- Sustainable and renewable

- Scalable for different applications (from small HHO kits to industrial plants)

- On-demand hydrogen generation

Electrolysis-based hydrogen is often referred to as “green hydrogen,” distinguishing it from grey and blue hydrogen made using fossil fuels.

🔧 How Electrolysis Works Step-by-Step

- Power Supply: A DC source (like a battery or power adapter) sends electricity to the electrolyzer.

- Electrodes: Stainless steel or titanium plates are commonly used for conductivity and durability.

- Electrolyte: A conductive liquid (often distilled water with added KOH or NaOH) allows current flow.

- Chemical Reaction: Water molecules split into H2 and O2 gases.

- Gas Collection: Hydrogen is collected at the cathode, oxygen at the anode.

📅 Types of Electrolysis Used in Hydrogen Systems

- Alkaline Electrolysis (AEL):

- Mature and cost-effective

- Uses liquid electrolyte (KOH or NaOH)

- Slower response time but ideal for constant loads

- Proton Exchange Membrane (PEM):

- Uses a solid polymer electrolyte

- Fast, compact, and ideal for variable power sources like solar

- More expensive due to precious metal catalysts

- Solid Oxide Electrolysis (SOEC):

- Operates at high temperatures (500°C to 850°C)

- High efficiency but still under development

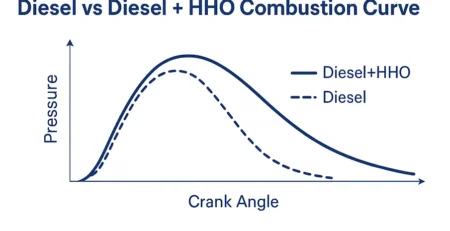

💪 Electrolysis Efficiency in HHO Systems

In HHO (oxyhydrogen) generators, the goal is to produce a mix of H2 and O2 in a 2:1 ratio. The efficiency of electrolysis is critical in determining how much gas is generated versus how much power is used.

Efficiency Formula:

Efficiency (%) = (Gas Output (LPM) × 186) / Power Input (Watts) × 100

Tips to Improve Efficiency:

- Use high-quality electrode materials

- Optimize plate spacing and surface area

- Monitor temperature (ideally below 60°C)

- Use PWM controllers to adjust current flow dynamically

👨💻 DIY vs. Professional Electrolyzers

While it’s possible to build your own HHO generator, the materials, design, and safety are often compromised. Professional systems like those by Hydrox Systems are designed with innovation, tested components, and smart electronics to ensure:

- Maximum gas output per watt

- Safe operation

- Long lifespan

- Easy integration into vehicles or industrial processes

🧳 Applications of Electrolysis-Based Hydrogen

Hydrogen from electrolysis is used in:

- Fuel cell vehicles (FCEVs)

- HHO retrofits for trucks and fleets

- Industrial welding and metal cutting

- Energy storage in hybrid systems

- Powering generators in off-grid locations

📊 Challenges of Electrolysis

- Energy Consumption: Electrolysis requires a lot of electricity, making the source of power crucial.

- Cost: High-efficiency electrolyzers are still relatively expensive.

- Water Purity: Impurities can reduce efficiency and damage equipment.

However, ongoing innovations and global climate goals are rapidly improving the technology and lowering costs.

📈 The Future of Hydrogen and Electrolysis

As the world shifts towards carbon neutrality, electrolysis will play a vital role in decarbonizing transportation, industry, and energy sectors. With green hydrogen emerging as a critical fuel of the future, understanding and improving electrolysis technology is more important than ever.

Innovations Ahead:

- AI-controlled electrolysis systems

- Hybrid solar-electrolysis setups

- Modular hydrogen generators for homes

🌱 Conclusion: Empowering the Hydrogen Economy

Electrolysis isn’t just a process—it’s a gateway to a cleaner, more efficient, and sustainable energy system. Whether you’re an eco-conscious driver, a fleet manager, or a green tech enthusiast, understanding how electrolysis works helps you make informed decisions and join the global push toward hydrogen-powered solutions.

Subscribe our Newsletter