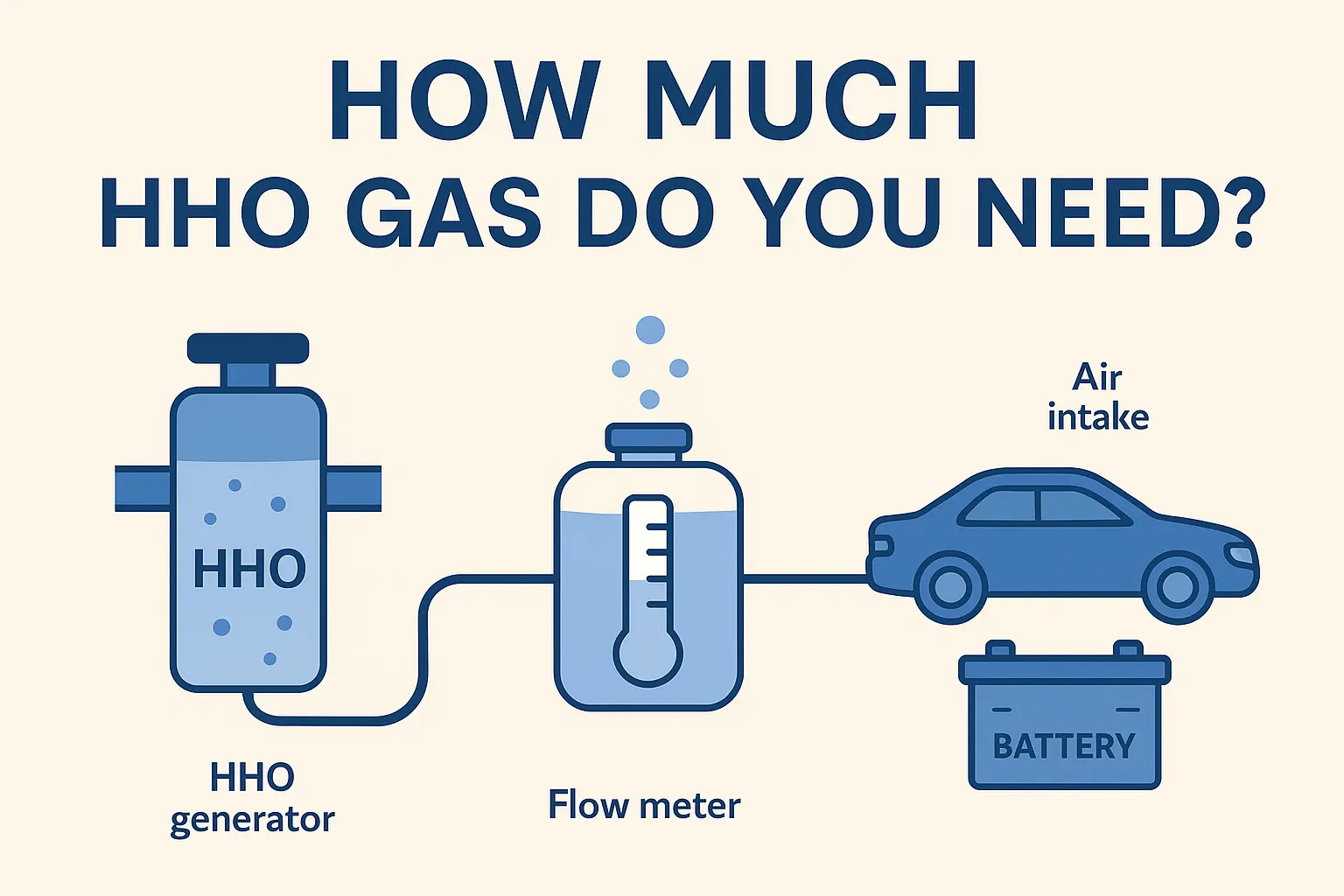

How Much HHO Gas Do I Need?

Calculating Flow Rates & Efficiency for Your System

HHO gas, or oxyhydrogen, is a clean-burning, energy-enhancing supplement for internal combustion engines and industrial processes. But to get the best results from your setup, knowing how much HHO gas you need—and how efficiently your system produces it—is crucial.

This article covers everything you need to know, from calculating flow rates to understanding gas demand based on engine size or use case.

🧭 Table of Contents

-

What Determines HHO Gas Demand?

-

🧩 Flow Rate Explained

-

📊 HHO Output by Engine Size (cc)

-

🔍 Calculating HHO Production Efficiency

-

⚙️ What Affects HHO Generator Output?

-

📉 Signs You’re Producing Too Little (or Too Much)

-

✅ Best Practices for Sizing an HHO System

-

🛠️ Example: Sizing HHO for a 2.0L Engine

-

🧠 Final Thoughts: Efficient, Smart Usage

-

🏷️ Tags

⚡ What Determines HHO Gas Demand?

The amount of HHO gas your engine or process needs depends on:

-

🔧 Engine displacement (cc or L)

-

🚚 Load and RPM range

-

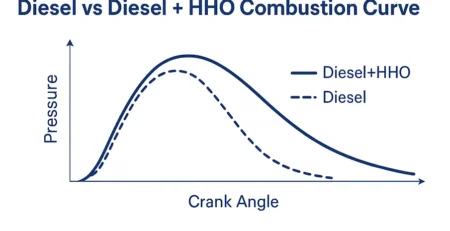

🧯 Combustion characteristics

-

⏱️ Duration of use

-

⚡ Voltage and amperage available

-

🌡️ System temperature

The larger or more powerful the engine, the more HHO gas is typically needed to enhance fuel combustion effectively.

🧩 What Is Flow Rate in HHO Systems?

Flow rate refers to how much HHO gas is produced per minute—commonly measured in liters per minute (LPM).

| Flow Rate | Description | Suitable For |

|---|---|---|

| 0.2–0.5 LPM | Low flow | Motorcycles, scooters, <1.2L engines |

| 0.5–1.5 LPM | Medium flow | Cars up to 2.5L |

| 2–4 LPM | High flow | Vans, trucks, 2.5L–5L engines |

| 5+ LPM | Industrial flow | Heavy-duty equipment, generators, >5L engines |

✅ Pro tip: Most passenger vehicles run well with 0.5–2 LPM depending on the driving cycle.

📊 How Much HHO Do You Need Based on Engine Size?

Here’s a general guideline for HHO gas demand:

| Engine Size | Recommended LPM |

|---|---|

| 0.8L–1.2L | 0.3–0.6 LPM |

| 1.3L–1.8L | 0.6–1.2 LPM |

| 1.9L–2.4L | 1.2–1.6 LPM |

| 2.5L–3.0L | 1.5–2.5 LPM |

| 3.1L–4.5L | 2.5–3.5 LPM |

| 4.6L–6.0L | 3.5–5.0 LPM |

| >6.0L | 5.0+ LPM |

🧠 Remember: These are averages. Real-world demand can vary based on altitude, fuel quality, and load.

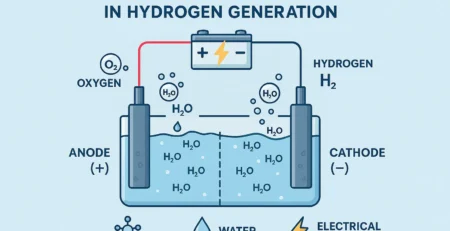

🔍 Calculating HHO Production Efficiency

HHO Efficiency Formula

Where:

-

186 Wh is the theoretical energy content of 1 liter of HHO

-

Input Power = Voltage × Amps

👉 Example:

If your system outputs 1.5 LPM using 12 volts at 20 amps, input power = 240 watts.

Note: Over 100% suggests calculation flaws or gas overestimation. Realistic electrolysis systems are 60–80% efficient.

⚙️ Factors Affecting HHO Output

| Factor | Impact |

|---|---|

| 🔌 Voltage & Current | Directly affect gas output |

| 🧪 Electrolyte strength (KOH/NaOH) | Higher concentration = faster electrolysis |

| 🌡️ Temperature | Warmer water = better conductivity |

| 📐 Plate design (size & spacing) | Optimized spacing = better yield |

| 🔄 PWM controller | Modulates efficiency & safety |

| 💧 Water purity | Distilled only! Minerals clog the cell |

📉 Signs of Low or Excessive HHO Output

Too Low:

-

No noticeable fuel savings

-

Minimal engine response

-

LED indicator off or blinking

Too High:

-

Bubbling in water filter

-

Generator overheating

-

Gas backfire (dangerous!)

-

System draws excessive current (>25A in small units)

🎯 The goal is to hit the “sweet spot” where gas production supports combustion without overloading your system.

✅ Best Practices for HHO Flow Rate Management

-

Measure LPM Accurately

Use a HHO flow meter or a gas displacement water bottle test. -

Monitor Current Draw

Install an ammeter to ensure optimal amps (typically 10–30A depending on system size). -

Use a PWM Controller

Adaptive PWM helps regulate power input and extends system life. -

Check Gas Quality

Install a bubbler and dryer filter to remove residual water and improve combustion. -

Log Mileage & Fuel Data

Use tracking tools (like Hydrox Systems’ fleet management) to correlate flow rate with real-world savings.

🛠️ Practical Example:

Sizing an HHO Generator for a 2.0L Petrol Engine

-

Engine: 2.0L

-

Target Flow Rate: 1.5 LPM

-

Voltage: 12V

-

Amps Needed: ~20A

-

Input Power: 240W

-

Recommended Generator: Medium plate cell (9–11 plates, but depends on the space between and density of electrolyte)

-

Electrolyte: KOH at 6% concentration

-

Add-ons: PWM controller, bubbler, LED indicator

📈 Expected Results:

-

10–25% improved MPG

-

Lower NOx and CO

-

Smoother idle

-

Reduced carbon buildup

🧠 Final Thoughts: Don’t Overdo It

Producing too much HHO isn’t always better. Gas that isn’t efficiently combusted is wasted.

That’s why high-efficiency systems like Hydrox Systems HHO generators are optimized to balance flow rate with your engine’s requirements—delivering real savings without compromising safety or performance.

✅ Always match generator output to engine demand.

✅ Measure and adjust your settings regularly.

✅ Install proper filters and regulators.

Subscribe our Newsletter