Can You Build Your Own HHO Generator? A DIY Breakdown

Can You Build Your Own HHO Generator? A DIY Breakdown

In the age of YouTube tutorials and Reddit forums, the idea of building your own HHO generator might seem tempting—especially if you’re mechanically inclined or on a tight budget. After all, with a few pieces of stainless steel, a water reservoir, and a power source, you could start producing your own oxyhydrogen gas at home… right?

Well, not so fast.

While a DIY HHO generator is certainly possible—and many enthusiasts have built working units—the real question isn’t can you build one. It’s whether it’s worth it in the long run. As a manufacturer who specializes in developing reliable, innovative hydrogen systems, let me break it down honestly and in detail.

🧰 The Basic DIY HHO Generator Concept

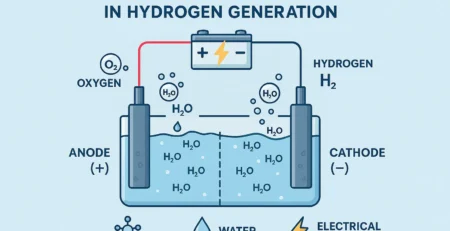

Let’s start with the fundamentals.

A basic DIY HHO generator includes:

-

⚡ Power source: A 12V car battery or similar

-

💧 Water reservoir: Usually a plastic container

-

🔌 Electrodes: Stainless steel plates or tubes

-

🧪 Electrolyte solution: Water mixed with NaOH or KOH

-

🧵 Wiring & fuses: To manage the electrical current

-

📦 Housing: Some form of casing to keep everything contained

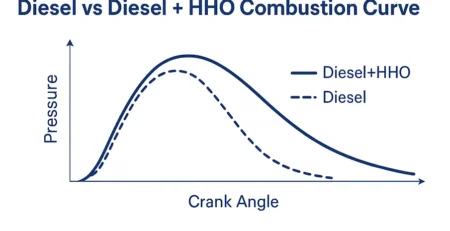

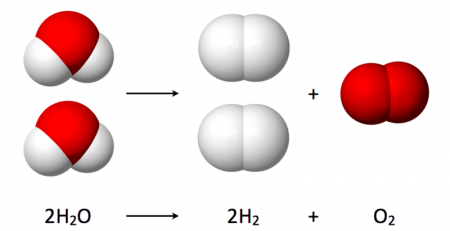

When powered on, current flows through the water between the electrodes, splitting water into hydrogen and oxygen gas (HHO). This gas is then directed to the engine’s intake manifold to enhance combustion.

Sounds simple enough, right? And in theory—it is.

But as we’ll explore, simplicity in design often leads to compromised safety, poor performance, and short lifespan.

🧪 Why DIY HHO Generators Often Fail

1. Cheap Materials = Short Life

Most DIY builders use cheap-grade stainless steel (like 304 or 316L), basic rubber hoses, and plastic containers not rated for heat or pressure. Over time, the constant exposure to electrolyte, current, and temperature fluctuations leads to:

-

Corrosion

-

Leaks

-

Melted parts

-

Reduced gas output

-

Frequent failures

In contrast, professionally built systems use laboratory-tested materials: high-purity stainless steel, reinforced thermoplastics, silicone seals, and industrial-grade electronics. These systems are engineered for continuous use over tens of thousands of kilometers.

2. Inefficient Gas Production

Without proper plate spacing, surface treatment, and current regulation, most homemade units produce low gas volumes for the amount of energy consumed. That means poor efficiency—more electricity is wasted as heat than converted into usable gas.

Professionally made generators solve this through:

-

Optimized surface design (neutral plates, dry cells)

-

PWM controllers to regulate power

-

Intelligent cooling

-

Flow sensors and temperature monitoring

These details may sound small, but they make a big difference in performance, efficiency, and safety.

3. Lack of Safety Features

One of the biggest risks in DIY setups is safety. Without proper flashback arrestors, pressure relief valves, or moisture traps, an HHO system can become hazardous—especially when used inside a vehicle.

Professionally manufactured systems include multiple layers of protection:

-

🔥 Flashback arrestors

-

💨 Pressure regulation systems

-

💦 Bubblers and dryers

-

🛑 Overload protection fuses

-

🌡️ Temperature and current monitoring

These features ensure that the gas is safely controlled and prevent backfires or leaks.

🏗️ DIY Cost Breakdown vs. Professional System

Let’s say you want to build a decent-quality DIY system. Here’s a rough breakdown of material costs:

| Item | Estimated DIY Cost |

|---|---|

| Stainless steel plates & laser cutting | €100–€180 |

| Plastic or acrylic housing | €30–€50 |

| Wires, relays, fuses | €20–€40 |

| Electrolyte (KOH/NaOH) | €15–€25 |

| Bubblers, tubing, clamps | €30–€50 |

| Flashback arrestor (DIY) | €15–€25 |

| Gaskets, seals, adhesives | €20–€40 |

| Total (materials only) | €250–€440 |

Now add your time: designing, cutting, assembling, testing, fixing leaks, adjusting flow rate, replacing corroded parts, etc. If you’re not a professional technician, that’s dozens of hours.

Then factor in:

-

Downtime from malfunctions

-

Cost of errors or dangerous failures

-

No warranty, no support

Now compare that to buying a professionally designed and tested Hydrox Systems HHO Generator, which starts at around the same price—yet comes with:

-

Industrial-grade materials

-

Safety features

-

Installation manual

-

Tech support

-

Warranty

Suddenly, the “savings” from DIY start looking pretty expensive.

🧠 What About Innovation?

Many DIY builders think they’ll “improve” upon basic designs. But real innovation in HHO technology takes:

-

Years of R&D

-

Proprietary components

-

Testing in controlled conditions

-

Sensor integration and software

At Hydrox Systems, we invest heavily in:

-

Adaptive PWM controllers

-

Smart diagnostics

-

Modular designs

-

Custom electrolyte formulations

-

Thermal and current-based optimization

These aren’t things you can just replicate with a soldering iron and a dream. It’s not about one part—it’s about a system built to perform, survive, and scale.

⚙️ So Should You Build One Yourself?

If you’re building one as a learning project or hobby—go for it! It’s a great way to understand electrolysis, gas dynamics, and engineering principles. However:

Don’t expect DIY systems to offer real-world reliability, performance, or longevity.

On the other hand, if your goal is to actually reduce emissions, save fuel, or improve engine efficiency on a day-to-day basis, invest in a tested system. It will save you time, money, and possibly your engine.

🌍 Why Professional Systems Matter in a Green Economy

As businesses, fleet operators, and governments push toward net-zero emissions, the demand for scalable, efficient hydrogen-based solutions is growing rapidly.

A DIY system simply doesn’t meet:

-

🔋 Commercial durability

-

🚚 Fleet compatibility

-

📊 Data monitoring and analysis

-

🔐 Warranty and compliance

Manufacturers like Hydrox Systems design equipment that can be integrated into sustainable transport, logistics, and industrial energy systems—helping companies meet ESG goals and cut operating costs.

In other words: This isn’t just a science experiment anymore—it’s the future of clean energy.

✅ Final Verdict

Yes—you can build your own HHO generator. But should you?

If your goal is learning, then building one can be a fun and educational experience.

But if your goal is real results, like saving fuel, reducing emissions, and improving engine performance in a safe, reliable way—then buying a professionally designed HHO system is the smarter move.

It’s not just about the parts. It’s about:

-

Precision

-

Durability

-

Innovation

-

Safety

- Certification

-

Support

When you buy a Hydrox Systems generator, you’re not just getting a product—you’re getting years of engineering experience, proven performance, and peace of mind.

Subscribe our Newsletter