How HHO Improves Diesel Engine Combustion?

How HHO Improves Diesel Engine Combustion: Efficiency, Flow Rates, and Combustion Curve Explained

As hydrogen-assisted combustion technologies gain attention across the transportation and industrial sectors, one question appears frequently:

Does adding HHO gas (hydrogen + oxygen) to a diesel engine improve combustion efficiency?

The short answer is yes—when used correctly, HHO can enhance the thermal efficiency of combustion, make the burn more complete, and reduce fuel waste inside the cylinder. However, the benefits depend heavily on the HHO flow rate, engine displacement, and how efficiently the HHO system is powered.

In this article, we break down the three most important points for anyone evaluating HHO technology for diesel engines.

1. Optimal HHO Flow Rate per Liter of Diesel Engine Displacement

The effectiveness of HHO supplementation depends largely on using the correct amount of gas. Adding too little delivers minimal benefit, while adding too much can increase exhaust temperatures or reduce engine efficiency.

Recommended Flow Rate

0.1 to 0.3 liters of HHO per minute (LPM) per liter of engine displacement

This range is widely considered the “sweet spot” for diesel engines.

Examples

| Diesel Engine Size | Recommended HHO Flow |

|---|---|

| 2.0L engine | 0.2 – 0.6 LPM |

| 5.0L engine | 0.5 – 1.5 LPM |

| 10L commercial truck | 1.0 – 3.0 LPM |

| 12–15L heavy-duty engine | 1.5 – 4.5 LPM |

Why this flow rate works

-

Hydrogen increases flame speed without overwhelming the mixture

-

Oxygen improves oxidation of unburned hydrocarbons

-

The electrical load remains manageable

-

Combustion becomes faster and more uniform

-

Engine components remain within safe temperature limits

This balance is critical for long-term reliability and measurable results.

2. Expected Thermal Efficiency Gains with HHO

Many laboratory and field tests show that introducing small amounts of hydrogen-rich gas into a diesel engine can improve thermal efficiency. This means more of the fuel’s chemical energy is converted into mechanical power and less is wasted as heat.

Typical Thermal Efficiency Improvements

-

Low load: +5% to +15%

-

Medium load: +3% to +10%

-

High load: +1% to +5%

Diesel engines often operate at partial loads—especially in city driving, construction, mining, and industrial equipment—where the benefits of HHO are the strongest.

Why Efficiency Improves

-

Shorter ignition delay: Hydrogen ignites rapidly, causing a smoother and earlier pressure rise.

-

Faster combustion: Hydrogen’s flame speed accelerates the burning of the diesel-air mixture.

-

More complete oxidation: Both hydrogen and oxygen help eliminate soot, CO, and unburned fuel.

-

Reduced diffusion combustion: The dirty, slow-burning portion of diesel combustion is minimized.

-

Lower carbon deposits: Cleaner combustion improves volumetric efficiency over time.

In simple terms: HHO makes diesel burn cleaner, faster, and more completely.

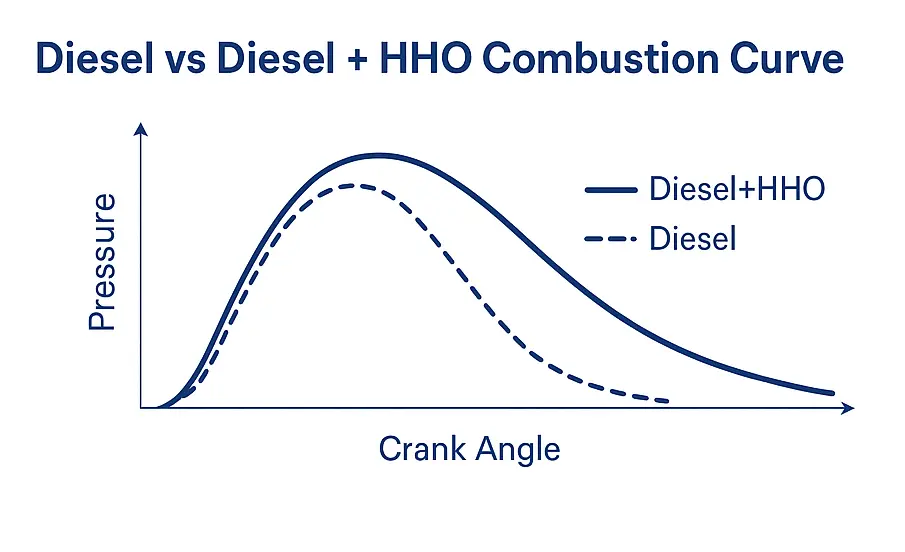

3. How Combustion Changes: Diesel vs. Diesel + HHO (Combustion Curve Explained)

To understand why efficiency improves, it helps to look at the combustion process inside the cylinder.

Conventional Diesel Combustion

Without HHO, diesel combustion typically shows:

-

A longer ignition delay (fuel accumulates before burning)

-

A sharp pressure spike (less controlled heat release)

-

Diffusion flames that create soot and incomplete burn

-

Peak pressure occurring slightly after the ideal crank angle

-

Higher heat losses to the exhaust and cylinder walls

This results in wasted fuel and higher emissions.

Diesel + HHO Combustion

When HHO gas is introduced in the correct ratio:

-

Ignition delay is shorter

-

The rise in pressure is smoother and more controlled

-

Combustion occurs earlier and closer to the ideal crank angle

-

The burn rate is faster, increasing torque output

-

Unburned hydrocarbons and soot are significantly reduced

Graphically, the pressure–crank-angle curve shifts slightly to the left (earlier ignition), peaks more efficiently, and tapers off quicker due to fewer unburned components.

This results in:

-

Higher brake thermal efficiency

-

Lower emissions

-

Less carbon buildup

-

Improved fuel utilization

In other words, the engine converts more fuel energy into useful power instead of heat.

Conclusion

Adding HHO gas to a diesel engine can significantly improve the combustion process—making it cleaner, faster, and more thermally efficient. The key factors that determine the results are:

-

Using the correct HHO flow rate

-

Ensuring the system is energy-efficient

-

Monitoring and optimizing engine conditions

When implemented properly, hydrogen-assisted combustion delivers measurable performance improvements, reduced emissions, and cleaner engine operation.

If your industry relies on diesel engines—transportation, logistics, construction, mining, or marine—HHO technology can be a practical step toward decarbonization and fuel cost reduction.

Subscribe our Newsletter