HHO Generator HS 4000 Pro + Dynamic PWM for Diesel

534,00 € Excl. VAT

Professional Hydrogen Generator kit suitable for Petrol injection or Diesel engines from 2500cc to 5000cc

Reduce emissions by 78% and save you fuel expenses up to 35%

This HHO Generator includes Dynamic PWM for Diesel engine

- Description

- Technical data

- Package contents

- Additional information

Description

Do you know that you can

SAVE FUEL and REDUCE EMISSIONS

by installing HHO CAR KIT in your vehicle?

How does the HHO car kit work?

How to assemble the HHO kit?

A simple explanation of the operation can see here:

Yes, you can save fuel and reduce emissions dramatically!

By adding HHO gas to your engine, you enrich the air-fuel mixture with Hydrogen and Oxygen gases. They improve regular fuels to burn more efficiently and thoroughly. Usually, most known fuels such as petrol, diesel, LPG, or CNG have an efficiency of around 25%. It means they create ONLY 25% mechanical power by their burning. Isn’t it too small? Yes, it is! As well, they pollute the air, which is a real issue with the smog. Another aspect, your engine also builds up carbon deposits.

The engine burns hydrocarbon fuels; as a result, we have mechanical power, CO2, CO, and Carbon soot accumulated over some significant engine parts. Affected parts of the engine are the EGR valve, air-intake pipes, and swirl flaps. Also turbo compressor, diesel particulate filter, catalytic converter, etc. These accumulated carbon deposits usually compromise the regular operation of the engine at a specific time. In most cases, before the engine has 150K kilometers, it already starts having carbon problems. Our company is working for over a decade to improve this technology. Hydrox Systems helps people get an advantage.

We have done lots of tests and spent a lot of materials to test and select the best ones. We spent a lot of financial resources, we also spent a lot of time, effort, and nerves to improve hydrogen technologies.

We’ve lost a lot of time developing the most effective and reliable HHO generators. But now you can use our products, produced based on all our experience and desire to build the most sophisticated HHO kits. So, don’t spend all of these resources above! We are already done this for you! Just buy it and use it!

HHO CAR KIT HS 4000 DRY CELL has13 PLATES 100% INOX with Titanium in the ingredients.

In this video, we show the main principle of the operation of the HHO kit. The produced HHO gas from the HHO CAR KIT is acting as additional fuel to the usual air-fuel mixture in any engine. Once the (H) Hydrogen is fuel and secondary, the (O) Oxygen is helping the burning process. HHO is the chemical abbreviation of Oxy-hydrogen.

HHO gas has two molecules of Hydrogen and one molecule of Oxygen. When we add HHO to a regular internal combustion engine, we practically enrich the air-fuel mixture with HHO, which is beneficial for any Internal Combustion Engine. Enriching the air-fuel mixture makes fossil fuel burn more efficiently and complete, which releases more mechanical power, of course.

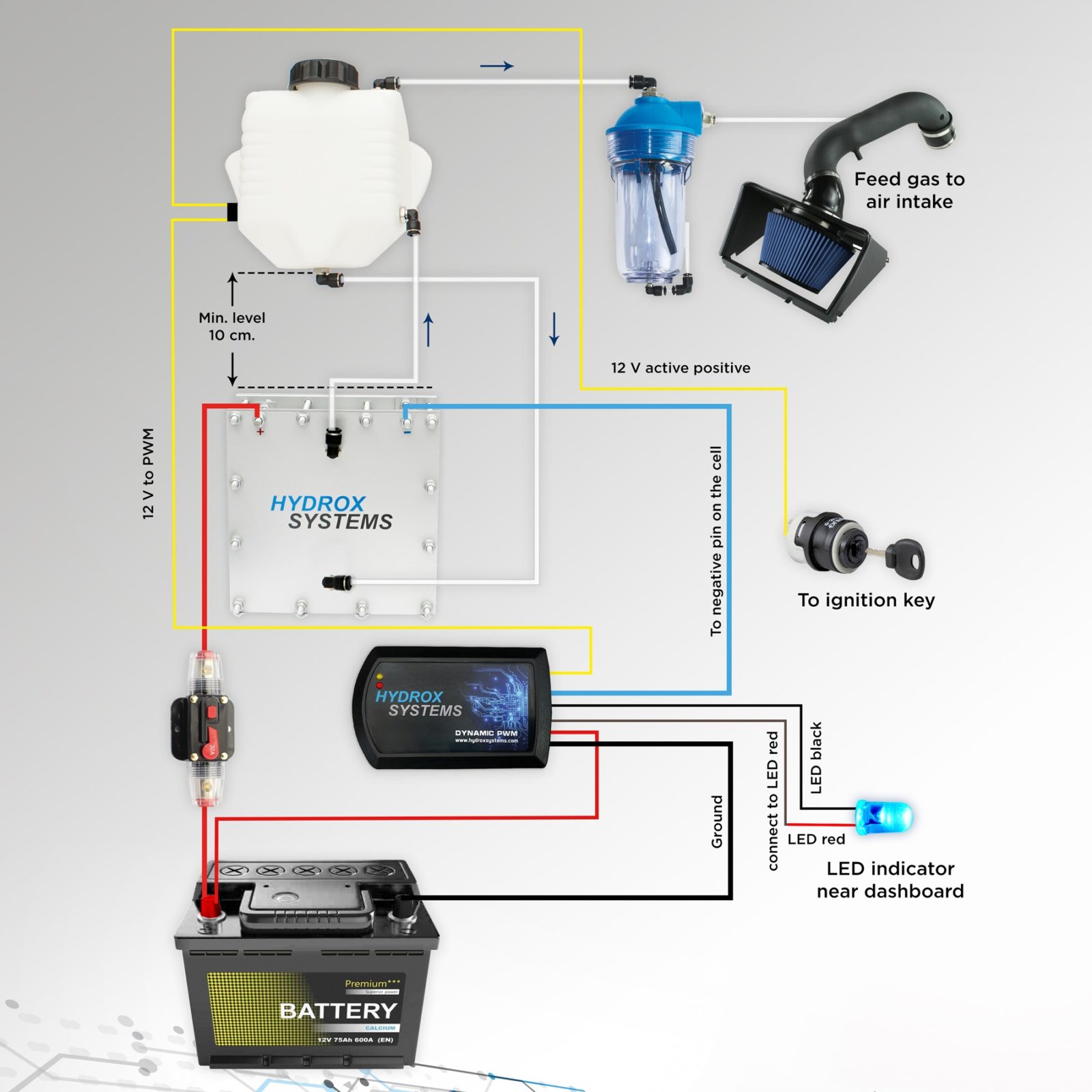

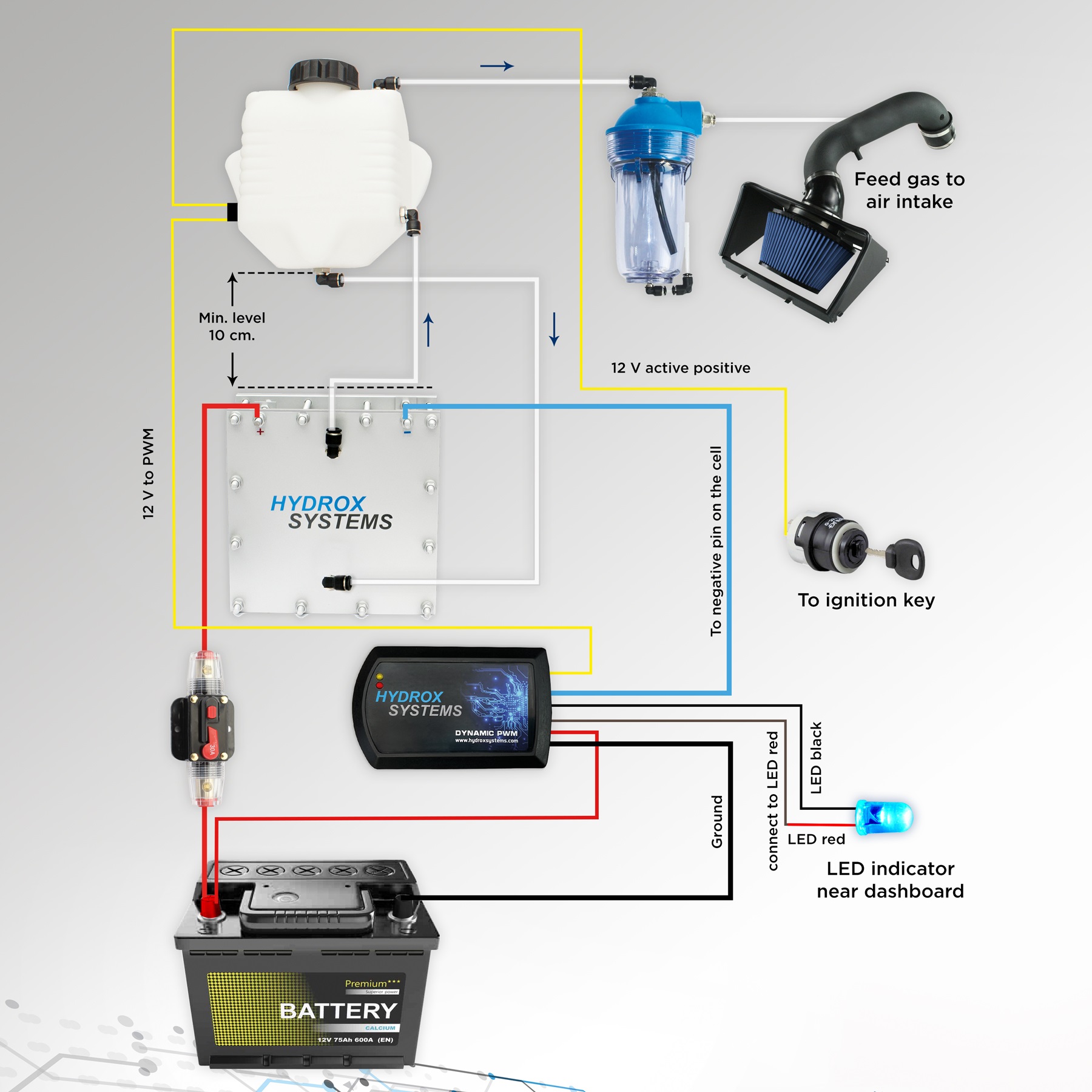

The HHO car kit needs two things to start operation: electrical power and electrolyte. Power 12-14.4V DC we take from the charging system of your vehicle, and we manage the proper power usage by our Dynamic PWM’s. There are two models: Dynamic PWM for Diesel 12V and Dynamic PWM for Petrol injection engine 12V. Dynamic PMW controls the usage of power and, of course, the production of HHO gas based on the RPMs of the Engine. Practically optimizing energy consumption, because on lower RPM your alternator can not carry a more significant load (Amps). Also, when the engine increases its RPMs by pressing the gas pedal, even the RPMs of the alternator are increased, and the alternator can carry a more significant load (Amps). Simply if you put too many Amps (load) on the alternator, the ECU of the engine will read this extra load, especially at lower RPMs.

For example, when you wait on idle RPMs at the traffic light and will start injecting more fuel to compensate for the extra load taken from the HHO system. That is why we developed this device called Dynamic PWM to be able to control better the amount (A) and production of HHO gas, based on the RPMs and engine needs. I will provide you with comprehensive information about the Dynamic PWM in another video here on our Youtube channel. You can feel free to subscribe to our Youtube channel and share our videos!

The electrolyte for the HHO car kit it’s made from Water and Potassium Hydroxide (KOH). Water is not expensive at the moment, and the KOH is a chemical, which also is not expensive. The KOH will be poured into the water and mixed until dissolved in total. The ratio of the electrolyte for our HHO Car Kits is 10%, which means 100 grams of Potassium Hydroxide mixed in 1 Liter of water. You all know that 1 liter of water is equal to 1 kg exactly. That is how we calculated a 10% electrolyte because we pour 0.1 Kg. KOH into 1 Kg water. Then it can be put into the HHO reservoir, so practically fill the HHO kit with its raw material. The HHO kit is ready for work now.

When we apply power to the dry cell, it will start producing HHO gas immediately. As you see in the video, the HHO Dry cell is on a lower level than the HHO reservoir. So, when you fill up the tank with an electrolyte, practically the electrolyte goes to the HHO Dry cell only by the gravity way. The produced HHO gas in the Dry cell is going up to the reservoir because it’s lighter than the liquid and pushes with the produced gas also some fluid. Based on this, we do not need a recirculation pump installed because the electrolyte is circulating between the reservoir and the dry cell by itself during operation.

After the produced gas is in the reservoir, it goes to the HHO bubbler. This device is mandatory for any HHO kit. It does not matter if it’s a dry cell or a wet cell. The HHO bubbler has three functions: 1. Take and keep the rough steam, which comes with the produced HHO gas from the HHO reservoir 2. Prevent any liquid (electrolyte, water steam, water) that goes into the engine air intake 3. Act as an anti-back spark device; the main advantage when you have an HHO bubbler in your HHO Kit is you do not need a one-way plastic valve. In any way, such one-way valves do not work. The one-way valves do not work because they do not prevent anything; the valves are fully opened by the vacuum created by the engine. That is why we do not use such one-way valves because they are merely useless!

After the produced HHO gas goes into the engine it enriches the air-fuel mixture. All our videos are made with honesty and based on all our experiments and experience! If you like our video, simply give us a Like, Share and Subscribe to our Youtube channel for more exciting videos about HHO gas! For any questions, just contact us at www.hydroxsystems.com or our FB page: https://www.facebook.com/HydroxSystems/

All our HHO Products such as HHO Generators, HHO bubblers, HHO reservoirs, and HHO electronics, and all of their components are designed and produced in European Union, and they comply with all standards required for such products.

Substantial advantages of our kit

HHO gas production – Despite its compact size, the cell is relatively small in proportion to the quantity of gas production ensuring optimal operation during all engine loads and its RPMs

The materials we use to create and produce our #HHO kits, and systems are all quality certified.

The Stainless Steel plates we use are 316L – INOX with a higher content of nickel, which is the rust-resistant component in the steel. All the Stainless steel plates are laser cut with very high precision. Besides, the stainless steel plates passed through chemical and mechanical treatment, thus allowing us to extend the working surface and longer work life.

The rubber we use for our gaskets is EPDM rubber—?ade by a special recipe to meet our technical requirements. The temperature range is between -51 to + 177 degrees. EPDM rubber is oil-resistant. The shape is square, which allows us to use more working surfaces for each Stainless steel plate. The thickness of the gaskets is proper for the normal conductivity process of the electrons between plates, also, with an appropriate ratio of electrolyte, which is very important for the regular operation of the #HHO generator during temperature amplitudes like severe winter or sweltering summer.

The hose connectors we use are the “Push-In” model, thus allowing you just to plug the hose into the connector, and that’s all. Furthermore, the Push-In connectors are 360 degrees movable from their base to allow easy installation. In our car kits, we use only PA12 hose, due to its high quality, instead of PVC, nylon, silicone, or a garden hose, which are not reliable at all.

We produce an HHO tank/reservoir with a volume of 1.4 liters. We use fire-retardant plastic to meet the requirements of the automobile industry for durability, long life, and compact size. It easily fits in all cars. Our reservoir allows the installation of a #water-level sensor, which you can add to your order during the order process, and it will come installed in your tank. The reservoir has non-vented c?p with a secure gasket inside that guarantees no leaks of electrolyte or #HHO gas. The function of the reservoir/tank is to keep more liquid in the system. This allows the circulation of the electrolyte between the Dry cell and the reservoir. When the Hydrogen comes from the dry cell, water vapor comes as well. Water vapor may carry microparticles from the electrolyte, which causes corrosion. So, the connector through which the gas returned to the reservoir is on a lower level, so the produce #HHO gas is bubbling through the electrolyte. The #hydrogen is cleaner from steam or any other particles. The first stage of cleaning the gas, but is not enough for us, and we always use a secondary Bubbler for more security.

The Bubbler has four functions. The first function is to clean the #HHO gas from steam and feed only clean gas to the air intake. The second function is to prevent reverse spark to the reservoir of the system. The Bubbler acts as a flashback arrestor. The third most important role is to determine the water level inside the Bubbler. Because if you drive long distances, for instance, and hold there more water vapor, the water inside will go higher level and could go to the air intake and probably into the cylinders. Imagine if water goes to your engine what it will cause?! Therefore we put a small pipe coming from the bottom of the Bubbler. It goes next to the sidewall of the Bubbler and goes up to a certain height. So, from this pipe, the extra water will just drop down, but also it will determine the water level inside the Bubbler and prevent the overflowing of water into the air intake.

The fourth function is that the same pipe is sucking air through it when you rev the engine at very high RPMs, so this releases the huge vacuum you have from the air intake and prevents the sucking of water into the air intake. Only we offer such a secure bubbler!

During the design of the #HHO generators, we were guided by the fundamental factors such as high efficiency, performance, compact size, strength, quality, long life, easy installation, and, last but not least, a good vision.

We recommend you to use Dynamic PWM for petrol or diesel engine! In order to control the amperes and the production of Hydrogen depending on the RPM of your vehicle!

Secondary elements of the HHO systems, like a tank, Bubbler, and Dynamic PWM designed and manufactured with requirements of compactness, strength, stability throughout a temperature, and stability of chemical bases. Quickest and easiest installation and, most importantly, consistency and certainty in connection with the Dry cell.

We do not use relays, one-way valves, and other non-sense redundant items in our systems.

The On/Off function is integrated into the Dynamic PWM, and it made a much more reliable Start-Stop function.

A one-way valve is always open during the engine work, and there is a vacuum, which is opening the valve!

Technical Data of the HHO Generator

Dimensions of the HHO cell: 190 mm x 190 mm x 110 mm (incl. the connectors)

Voltage: 12 – 14.4 VDC (from vehicles battery)

Material: steel INOX 316L SS

Configuration of the plates: – NNNNN + NNNNN –

(+ positive, N-neutral, – negative)

Amperage: 3 to 30 Amp

Working surface: 4394 sq. cm

Capacity: up to 2.5 liters gas per minute @20 amps

The required ratio of the electrolyte (water-KOH): 5%-15%

Hose connectors: Push-In type

Package includes:

HHO Dry cell -1 pc.

HHO tank/reservoir 1.4 liter – 1 pc.

HHO bubbler – 1 pc.

Dynamic PWM for Diesel – 1 pc.

Tubing – 4m.

Wires:

Red 6 sq.mm. – 3.00 m

Black 6 sq.mm. – 2.00 m

Blue 1.5 sq.mm. – 3.00 m

fuse and fuse holder – 30 amps -1pc.

Inlet gas connector – 1pc.

All electrical connectors

Installation instruction + scheme (Only digitally will be sent to your email)

Instructions for use (Only digitally will be sent to your email)

Additional information

| Weight | 7,60 kg |

|---|---|

| Dimensions | 40 × 33 × 20 cm |