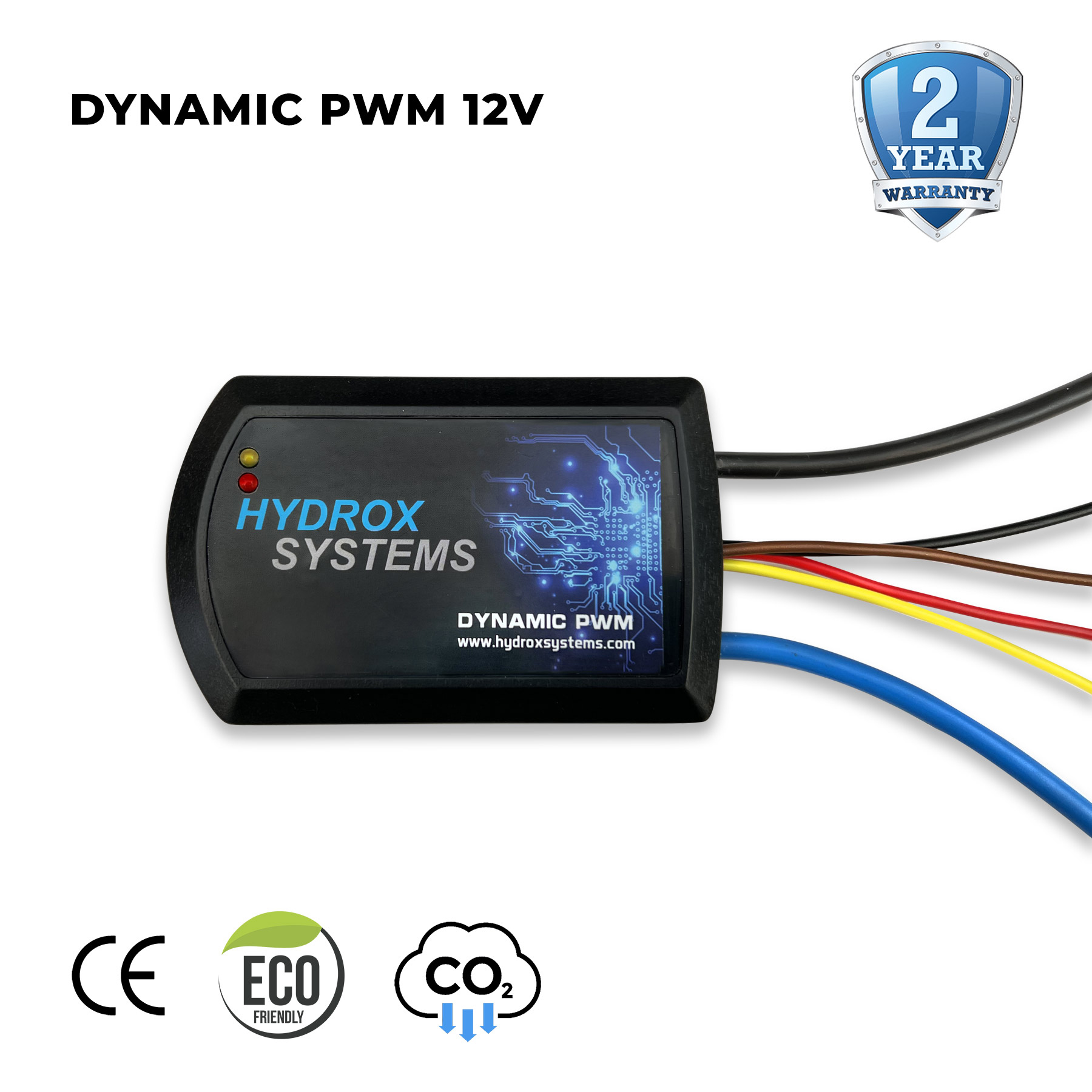

Dynamic PWM for Diesel 12V

189,00 € Excl. VAT

Dynamic PWM for a Diesel 12 V – Fully automated control for your HHO Generator.

It optimizes the HHO production and energy consumption based on different parameters of the charging system, electrolyte density, temperature, etc.

Compatible with all Diesel engines with a 12V charging system.

No need for relays

No need for a cooling fan

Automatic ON/OFF

Automatic current regulation

Easy to install

- Description

- Additional information

Description

Dynamic PWM for Diesel 12V

Why do I need it?

Control is one of the essential elements in a particular system if we want to have efficiency. Proper power control is significant because we have limited power resources from the charging system on board any vehicle.

Dynamic PWM for diesel 12V is the control device of a Hydrogen system.

Latest technology facts!

As we all know, most cars these days have substantial capacity alternators, but these alternators only charge the battery sometimes. The alternator is charging until the battery gets to full at 14.5V, then the alternator stops charging. Respectively, the alternator starts to charge the battery again when discharged to 13V. Car battery manufacturers find that their batteries have longer lifespans when charged and discharged cycles. Hence, car manufacturers decided to follow this strategy to extend the lifespan of the alternator also.

In any way, our Hydrogen system produces HHO gas as a supplement fuel and catalyzer for better and complete fuel burning. We do not substitute a certain amount of fuel, just adding HHO gas which helps the burning process to make the regular fuel burn more completely, release more mechanical energy, and eliminate the emissions.

The idea…

So, that was the main reason we upgraded the previous model of Dynamic PWM, which was to control the Amps and production of HHO gas based on the RPMs of an engine.

We decided to control the production of HHO gas based on the condition of the charging system (battery and alternator) and RPMs of the engine (respectively, charging Volts at idle RPMs and charging volts at higher operational RPMs).

If the battery is charged to a maximum of 14.5V, we can use more power to produce more HHO gas. When it starts to discharge to 13.0V slowly, we will use progressively less power so that the alternator will get an advantage to be able to charge the battery again to its maximum.

If the alternator is in good condition and charges the battery sufficiently, we can use more resources to produce more HHO gas. Of course, if the alternator is worn and it’s not charging the battery enough, we will use fewer power resources for our Hydrogen system.

Suppose the alternator is too worn and the voltage goes below 13V, even at higher operation RPMs of the engine. In that case, the PWM automatically stops the Hydrogen system to prevent any power usage when the charging system is not working correctly.

This way, we will never harm the battery and the alternator, and at the same time, we can use the maximum of that extra power from the charging system to produce more Hydrogen gas.

Method of operation!

We have done hundreds of tests on different vehicles, at different loads, with various consumables ON and other conditions, so we have collected a database of information to make the best software functionality. We spent about three years developing the latest device because we wanted to make it precise, efficient, and user-friendly!

The Dynamic PWM version 6.0 operates between 5A and 16A depending on variables such as charging system condition, temperatures, the density of the electrolyte, conductivity, resistance, and other parameters so that we could optimize the process to the maximum. Besides that, we made it fully automatic, so there is no need to regulate human intervention. If all wires are correctly connected to the HHO kit, there is no possibility of mistakes!

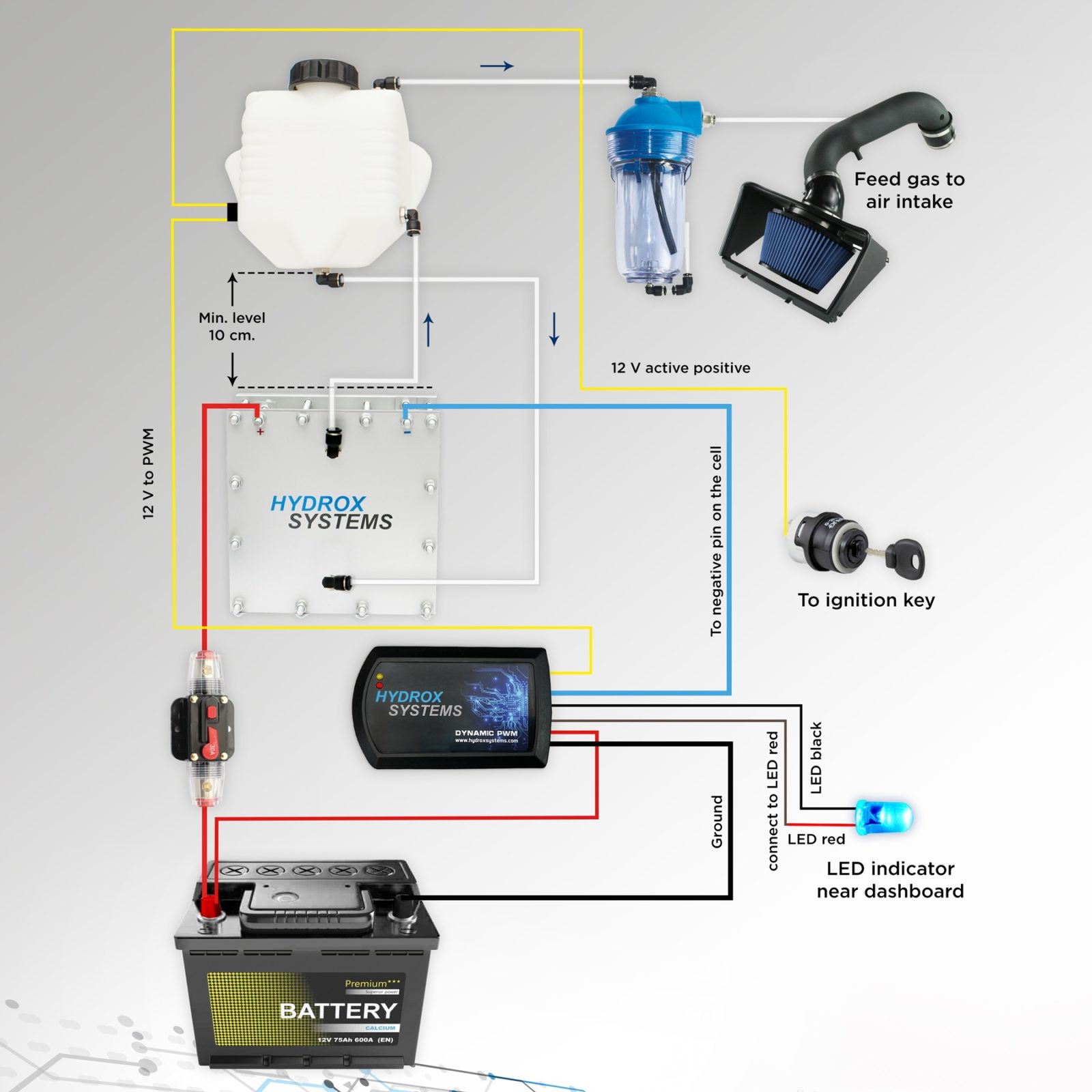

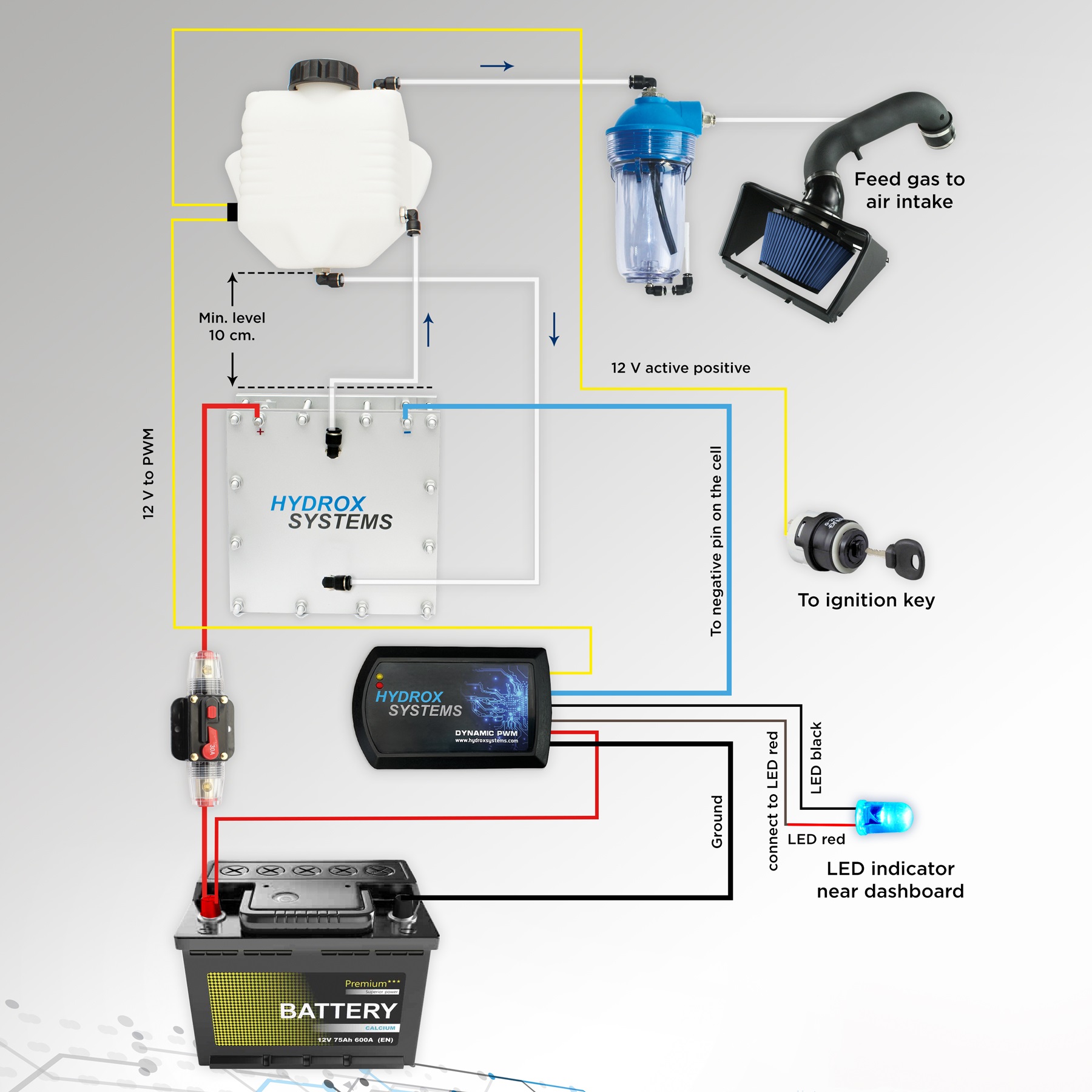

Wiring diagram:

Positive sides of Dynamic PWM for Diesel 12V

- Your system does not need a relay

- The system does not need even an ammeter

- You don’t need you always to check the electrolyte density

- External LED showing you when the system is operational

- No radiator

- No fan

- Dynamic PWM has an automatic ON/OFF

- Very small and compact

- Very easy to install

- Saving your alternator and battery

- Energy efficient

- Installation takes 5 minutes

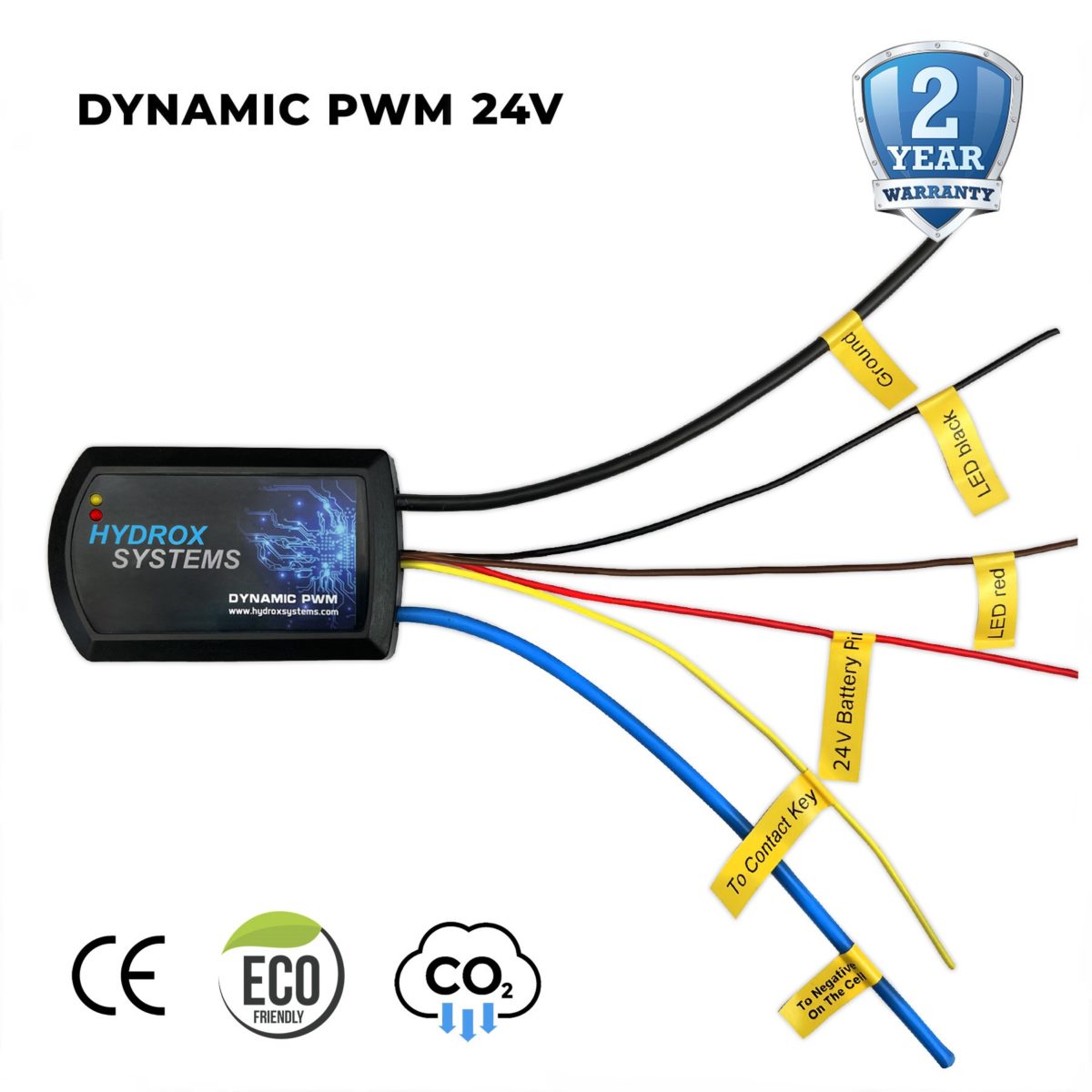

The warranty is two years from the date of purchase!

It may not be fully compatible with equipment other than Hydrox Systems!

The warranty is not acceptable with hardware other than Hydrox Systems!

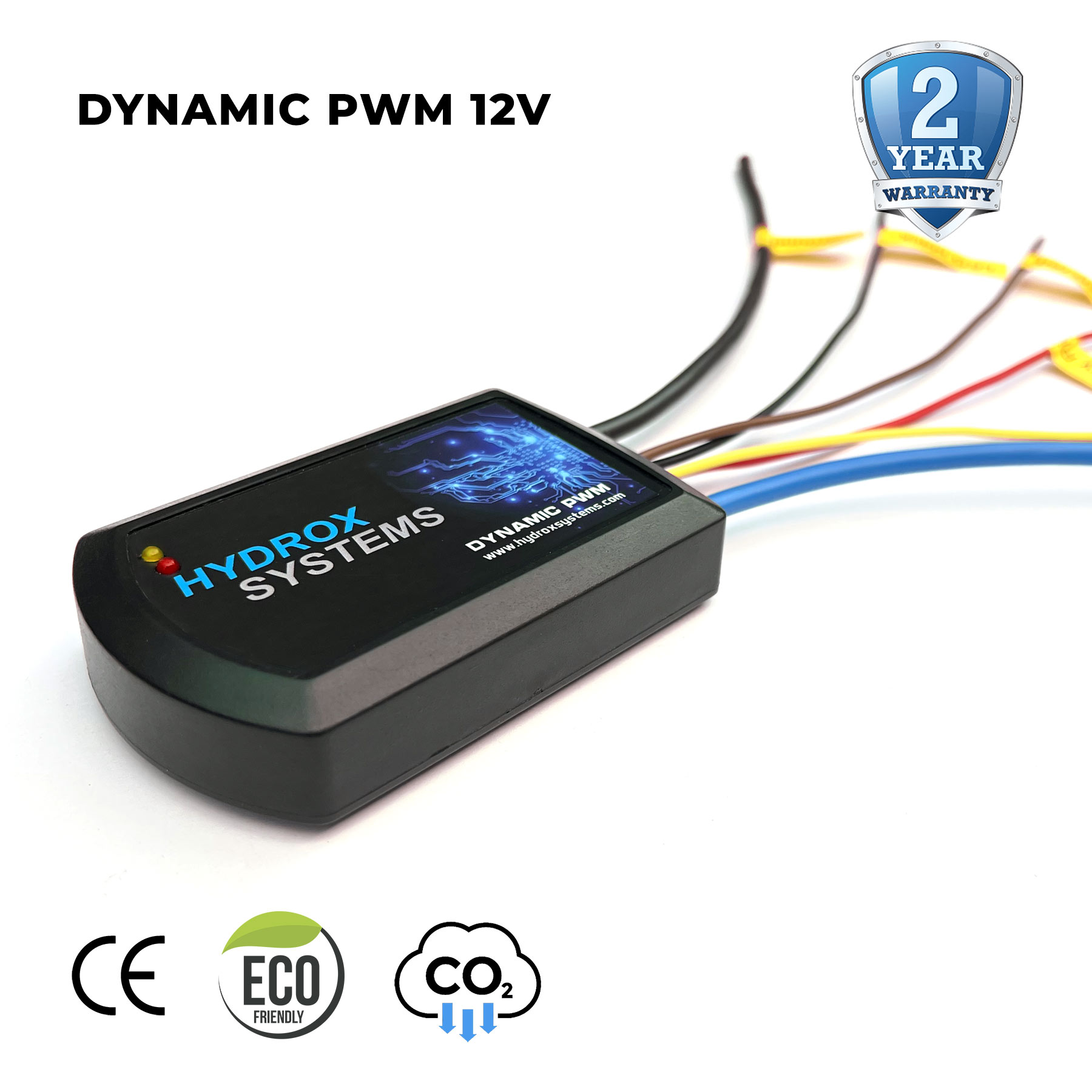

Measures of the device: 10cm. X 6cm. X 2cm.

Weight without packaging: 200 grams

Additional information

| Weight | 0,5 kg |

|---|---|

| Dimensions | 10 × 10 × 20 cm |